What’s the Big Idea?

For many years, Vassilis Syrmos didn’t spend much time thinking about business. An electrical engineer with a Ph.D. from Georgia Tech and a new career in academia, he was happy to focus on pure research. “When you’re a young assistant professor,” he explains, “your science is the most important thing to you.”

That changed in the mid-1990s, when he spent a year and a half on sabbatical leave as a research fellow at Boeing, working on commercial aircraft design for United Airlines. “Being exposed to how you translate your customer requirements and desires to the actual product and specifications was an eye opener for me,” he says.

The experience sparked an interest in the business of engineering for Syrmos, who went on to collaborate with Boeing on more projects. Today, as VP of research and innovation at UH, he’s among the leaders driving efforts to commercialize UH research and help more scientists bridge the gap from lab to business, through programs such as XLR8UH. The proof-ofconcept center, which launched last fall, offers research teams training, mentors and funding to bring their innovations to market.

At the same time, the university’s Office of Technology Transfer and Economic Development will likely get an overhaul under the leadership of local venture capitalist William K. “Bill” Richardson, who was named interim director in November. The office licenses and protects university intellectual property and sometimes acts as matchmaker between faculty and industry.

Richardson says his first priority will be to improve communication with professors about the commercialization process, and to work closely with industry leaders to give feedback on projects emerging from UH research.

“We’ve dramatically ramped up the amount of outreach,” he says. Omar Sultan, a partner at Sultan Ventures and managing director of XLR8UH, says that, historically, UH has been in the top third of universities for the amount of research funds it receives, but in the bottom third for the number of innovations it launches as commercial businesses.

“We’re looking to change those numbers and bring more of that intellectual property out into the marketplace,” he says.

More than simply cherry-picking hot new technologies and infusing them with cash, Sultan says, education is the program’s first goal. Sultan says his vision is to develop the next generation of entrepreneurs in Hawaii.

“It’s more than technology that makes these projects successful, it’s also the talent pool,” he says. “If we have 10 kick-ass technologies, but only three kick-ass entrepreneurs, that’s a big problem.”

That’s one reason Hawaii’s program invites applications not just from faculty, but graduate students, undergrads and UH alumni – a policy that sets it apart from other university business accelerators around the country. Syrmos thinks that inclusiveness could also give XLR8UH the “critical mass” it needs to succeed over the long term without running out of ideas.

“We’re an island, there’s no Silicon Valley here. We have a limited amount of intellectual capital,” he says. “The faculty doesn’t change, but the graduate students and undergraduate students keep flowing through.” The new program has felt growing pains, most uncomfortably in hitting bureaucratic snags that blocked the release of funds to most teams in the first cohort. Sultan says the process of investing in commercial ventures – the funds aren’t considered grants, but are provided in exchange for a stake in the eventual business – was more complicated than it’s been at similar programs, because UH is a public university.

“Some teams were understandably getting a little frustrated,” he says. “Everybody wants to do it, it was just figuring out the proper mechanism.”

As of March, it appeared the problem was being resolved, Syrmos adds.

On the flip side, organizers hope the program will eventually net revenue for the university, both as a stakeholder in the patents generated by UH faculty and as an investor in businesses launched through XLR8UH. Funds raised would go to support commercialization programs, with the goal of eventually making them self-sustaining. And Syrmos notes that, for universities with a track record of launching successful ventures, like Stanford and MIT, the biggest financial return often comes from the philanthropy of alumni who strike gold. But, Syrmos says, the ultimate reward is seeing faculty launch successful startups – and go on to hire home-grown expertise.

“Being able to employ our own graduates, that’s a huge satisfaction to me.

FOUR UH PROJECTS TO WATCH

-

THE BUSINESS: MorphOptics

The innovation: Photovoltaic concentrators

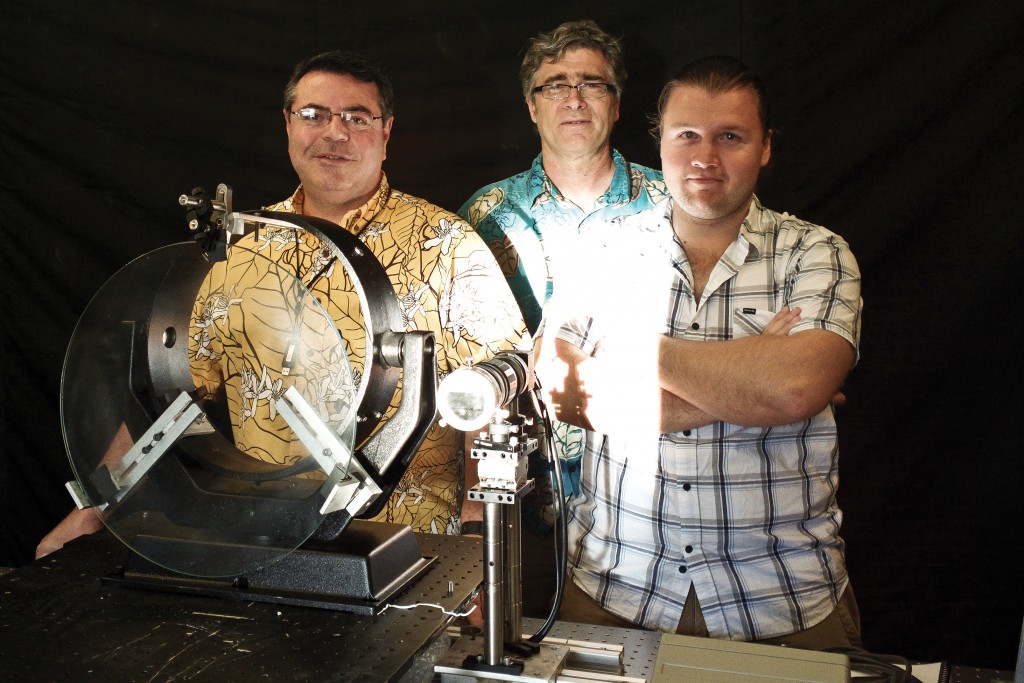

The Pitch: An astronomy dream team takes its expertise from solar telescopes to solar panels.

For Jeff Kuhn and Joe Ritter, the “eureka” wasn’t when they solved a major optical problem that had been perplexing builders of large telescopes, it was the moment they figured out how to sell it.

Together with their team from UH’s Institute for Astronomy, Kuhn, an astronomer, and Ritter, an electrical and optical engineer, had designed a low-cost way to produce the superprecise mirrors needed for telescope optical systems. Knowing their invention could make the cost of building a solar telescope significantly cheaper, they applied for and were accepted to the first cohort of XLR8UH last year, to get help commercializing their product.

But, instead of teaching them how result: a four- to five-time increase in the amount of power produced per square foot of solar panel.

“Your roof space is now four times as valuable, because you can produce four times as much power at the same price,” explains Kuhn. Ian Cunnyngham, a scientific programmer at the Institute for Astronomy and a member of the team, says the realization that they could apply their technology to PV was “pretty exciting.” “Of course, the solar-energy market is astronomically bigger than university or hobby astronomy,” he says.

The Maui-based team traveled to Honolulu every Saturday from September 2014 through January 2015 for workshops alongside other XLR8UH teams and to meet with mentors and business experts, who helped them develop their business model and work on their pitch. “It’s tough to be a business person when you’re used to academics,” says Cindy Giebink, a software/systems engineer at the institute and a member of the MorphOptics team. “They made us think in different ways.”

But the team was accepted to the second cohort of XLR8UH, providing an opportunity to take its business plan a step closer to launch, and standing to receive an additional $50,000, once the process for releasing the funding is resolved.

Vassilis Syrmos, VP of research and innovation at UH, says MorphOptics was exactly the kind of project he hoped XLR8UH would help launch, because it involved a team with an internationally respected scientific background and built upon the university’s research strengths.

“We’re pretty much second to none when it comes to astronomy, so when you apply that to solar-energy concentration, to me that’s pretty cool,” he says. “Even if 50 percent of what they claim is true, it’s going to be revolutionary, in my opinion.”

2. THE BUSINESS: Akabotics

The innovation: Microdredgers

The Pitch: “Like the Roomba, for waterways”

Watching heavy machinery dredge disgusting muck out of the Ala Wai Canal and haul it away by the truckload made Newton Parks wonder: Why let the stuff build up in the first place? “Sediment buildup is a slow, steady process, so what’s the solution for that?” he says. “It’s not a huge machine that comes in and does a root canal. It should be more like erosion, slowly chipping away at it and working at a slightly faster pace than the sediment comes in.”

Parks, currently pursuing his doctorate in architecture at UH, brought the idea to his girlfriend, Monica Umeda, a master’s student in electrical engineering.

The pair are interested in designing robots that solve problems and had been looking for a way to go into business together.

Their solution: a compact, robotic “microdredger” that would stay on top of the problem by removing small amounts of gunk every day. The more they studied the issue, the more they realized that the inefficiencies in dredging were an international problem. In addition to the high cost of using heavy machinery, large dredging projects are dangerous, and disrupt commerce and recreation – closing waterways for months or years at a time. They’re also bad for the environment by dislodging huge plumes of silt that suffocate plants and animals downstream or offshore.

“Right now, the solution is almost worse than the problem,” Parks says. “It just doesn’t seem like the proper tool set.”

Although the pair are students at UH, they filed for a provisional patent independently, noting that they came up with the idea on their own, using their own resources, and did all the work on the project off campus, including prototyping in their garage. They entered the idea for “Akabotics” in a local business-plan competition and, although they didn’t win any money, they received encouragement and positive feedback, and connected with mentors and potential investors.

They were accepted to XLR8UH’s second cohort, starting the program in February. Although UH and Sultan Ventures will get an equity stake in the company in exchange for the up-to $25,000 Akabotics is eligible to receive through XLR8UH, Umeda and Parks note that they alone control the intellectual property for their design.

Omar Sultan, partner at Sultan Ventures and managing director of XLR8UH, says Akabotics is an “inspiring story” of two students who took full advantage of the opportunities available.

“XLR8UH is excited to be that next step in their growth and be there to help turn their innovative ideas into startups formed here in Hawaii,” Sultan says. Umeda says the program has helped them refine their business plan in “super depth.”

“It really forces us to nail down exactly who the customers are, what they want and how we’re going to get there,” she says.

Beyond business guidance and the opportunity to get feedback from real investors, Umeda says, the program has given her a sense of community.

“I think it helps to look around the room and see 30 other people doing the exact same thing you’re doing,” she says, “because sometimes it gets a little lonely.”

3. THE BUSINESS: KinetiCor

The innovation: An MRI Image stabilizer The Pitch: Hospitals could say goodbye to blurry scans with motionsensing technology

People who’ve undergone an MRI scan know what an ordeal it can be: The patient must fight claustrophobia and hold perfectly still for up to 45 minutes within a cold, clanging, coffinlike tube. The slightest twitch can blur the scan, sending the patient back in to do it again.

That’s the problem Thomas Ernst set out to solve. A physicist with UH’s Neuroscience and MRI Research Program, a lab hosted by The Queen’s Medical Center, Ernst and his team had an idea to stabilize MRI images with a system not unlike an ultrahigh- definition version of the motioncapture technology used in film and TV. With a $4 million grant from the

National Institutes of Health, Ernst’s team designed a marker that goes on the patient’s face. A special camera detects the marker’s movement and feeds information to the MRI machine in real time, allowing the scanner to adjust to the patient’s new position as quickly as 60 times per second. The result: a crystal-clear scan every time.

The three prototypes created by Ernst’s team were installed in university MRI labs, where they improved scans done for brain research. But Dr. Jeffrey Yu, chief technology officer for The Queen’s Health Systems, saw a wider application in this particular project among others. “Maybe I’m a little biased because I’m a radiologist,” he says, “but I thought this was the most promising work.” Yu joined the project, helping oversee the patent process and working to secure $900,000 in seed funding from the UH Foundation, HMSA and

The Queen’s Development Corp. to launch KinetiCor. The company began manufacturing its sensors to retrofit research scanners, selling between six and nine units a year to generate $2 million in sales over two and a half years. At the same time, KinetiCor pursued FDA approval to use the device in medical applications and began discussions with a leading MRI vendor about offering the technology on its machines. At first, the vendor wasn’t convinced its scanners needed the upgrade.

But KinetiCor’s team showed them that the improvements would do more than make MRIs easier on patients. Yu points out hospitals lose an average of $100,000 per machine a year because they have to re-do shaky scans. And, as high-definition imaging make MRIs even more sensitive, he notes, theproblem is getting worse.

After two years of negotiations, the MRI vendor agreed to fund the project, with plans to initially offer the sensors as an option on its new scanners, and the possibility of offering them as a retrofit in the future. Yu expects the KinetiCor sensors will be available for medical use around 2017. Even though the sensor started as “pure research,” Ernst says it was easy for him to make the leap to seeing its potential as a commercial product.

“I always thought it wouldn’t make sense to spend $4 million to develop this, only to have three prototypes running in the end.”

4. THE BUSINESS: Adama Materials

The innovation: A new way to weave carbon nanotubes The Pitch: With a tougher carbon composite, you’ll have to hit the dock twice as hard to ding your yacht.

It’s hard to imagine life without carbon nanotubes. Thanks to their incredible lightness and strength, the microscopic fibers have become a ubiquitous component in materials like carbon fiber, used in everything from surfboards to spacecraft. Since their use exploded in manufacturing about a decade ago, the race has been on to develop the next generation of materials from this technology.

So when Mehrdad N. Ghasemi- Nejhad, a professor and department chair of mechanical engineering at UH, invented a method of growing nanotubes that would interlock like miniature Velcro, potentially building a composite material that would be stronger and tougher, it was an exciting discovery. He also discovered that extremely small amounts of nanomaterials could have a major impact on the properties of the resin used in the composite.

He found a partner in Donavan Kealoha, a UH law student with an interest in business and experience entering business-plan competitions.

The two launched Adama Materials in 2008, going from competition to competition, winning money to pay for patent costs and get the company off the ground.

“It was like a full-time job for a while,” Kealoha says of the circuit. The team received support from Susan Yamada, executive director of the Pacific Asian Center for Entrepreneurship at the Shidler College of Business, who provided space for them to meet, “moral support” that included flying to the mainland to encourage them at competitions, and offering them valuable introductions.

Those connections eventually snagged their lead investor: now- CEO Frank Thibodeau of Artiman, a Silicon Valley-based venture fund with a focus on hard-science technologies that haven’t yet been commercialized. “We saw a lot of potential,” he says.

“It’s a big market, we thought it was ripe for innovation, we had the core of a good team in place, an established body of intellectual property.

All of the pieces seemed right.” But while work on the core technology was moving forward in Nejhad’s lab, the team hit a snag with the development of the resin that would bind the fibers together into a composite material. Like many other labs working with carbon nanomaterials, they had trouble with the basic compatibility of the two materials, making the results of their testing inconsistent.

Chemical engineering “isn’t a strong suit for UH,” Thibodeau says, “as opposed to mechanical engineering, which really is, so there was a collective decision to find a group of polymer engineers who could take us to the next step.”

They ended up partnering with a nationally known chemical engineering and materials science lab at the University of Minnesota. That team was able to figure out a solution to the problem, and recently announced its experimental results at a major composites trade show in October. “I think it’s fair to say that all the big resin producers thought what we’re doing is really compelling, and it’s reached the point where we’re now doing in-house testing with a couple of them,” Thibodeau says. He expects a commercial launch for the product by the end of the year.

While lab work has moved to the mainland, Hawaii remains “very much involved,” with Nejhad directing and overseeing the research, and intellectual property rights remaining with the technology’s inventors and UH, Thibodeau says. The site of future manufacturing has yet to be decided. Although Adama’s commercial launch is now more than seven years in the making, Thibodeau says, it’s not surprising that its path has taken twists and turns, given the nature of the company’s product.

“If you’re going to make stuff, that takes longer than writing code,” he says. “I think there are a lot of VCs that have shied away from real manufacturing, because it not only takes longer, it tends to be a lot more expensive. But, at the end of the day, you’re really building long-term value.”