Pass or Fail: Food Inspection

Inside the food and restaurant inspection process, where sanitarians look for things that could make you sick

Michael Okamura isn’t a police officer and doesn’t wear a uniform, but he carries his badge and ID while on the job. His workplace is any food establishment between Haleiwa and Temple Valley.

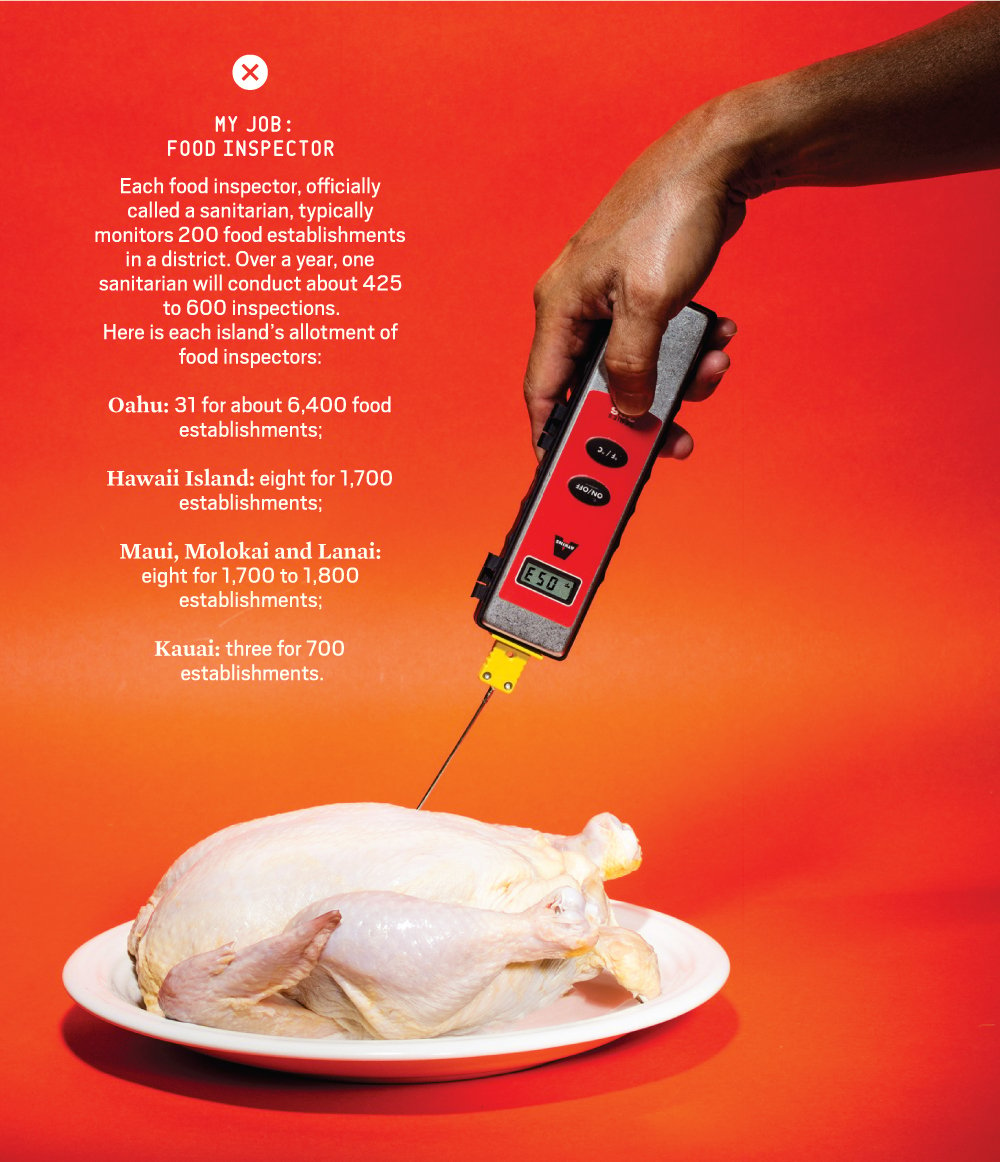

Okamura is one of 50 state food inspectors who enforces food safety rules at Hawaii’s 10,500 restaurants, food trucks, grocery stores, food manufacturers, schools and other institutions.

“We’re not like food policemen. We’re actually partners with the food establishment … as we both have a common goal. Our common goal is to ensure that safe food is served to the public,” says Okamura, who has been a food inspector or “sanitarian” for 36 years.

Sanitarians inspect each place at least once a year, checking for risk factors that can make customers sick. Those factors include poor personal hygiene by kitchen workers, inadequate cooking, holding food for too long or at an improper temperature, and contaminated equipment or food.

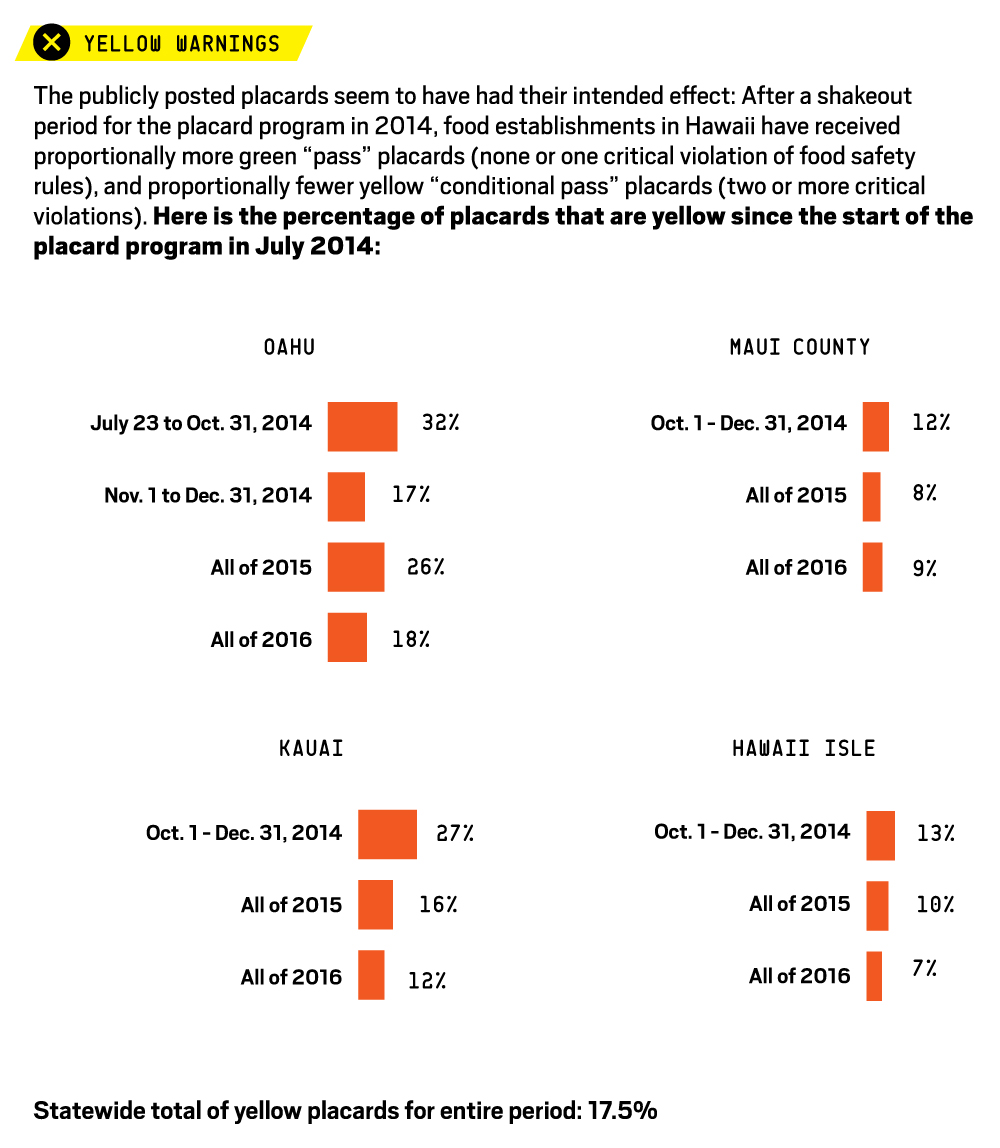

You’ve seen the results of the inspections since July 2014 in the colored placards on a restaurant’s front window or outside wall. Green is “Pass,” yellow is “Conditional Pass” and red is “Closed.” The placards are part of the state’s color-coded food inspection grading system, which encourages voluntary compliance with the state’s food safety rules through social pressure. Peter Oshiro, program manager for the state Department of Health’s Sanitation Branch, says the system has worked well, decreasing the number of violations found in food establishments.

The state has conducted more than 20,000 routine inspections of food establishments under the placard system, Oshiro says, with only three resulting in closures: “That’s a huge success rate.” Closures happened maybe once or twice a year before this system was in place. However, most food establishments were given major violations upon being inspected, and sanitarians had to go back three to four times before the establishment was considered compliant with the state’s rules. The placards have significantly reduced that follow-up rate as all violations are typically corrected by the first follow up.

HIGH OR LOW RISK

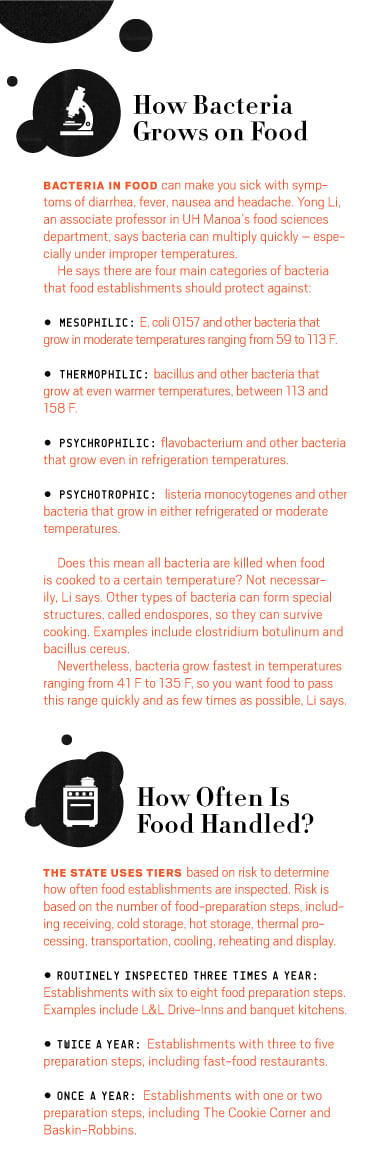

Inspections are conducted once, twice or three times a year, depending on the risk the food establishment presents to public health. Oshiro says the risk category is determined by how many food preparation steps an establishment has: About 25 percent have lots of steps, so they are high risk, 30 to 40 percent are medium risk, and about the same percentage are low risk.

Sanitarians also inspect before establishments open and after complaints are received about foodborne illness. They also inspect public pools, tattoo shops and mortuaries, though food safety is about 90 percent of a sanitarian’s job, Oshiro says.

Inspections can last anytime from half an hour for an establishment with simple operations, like serving ice cream, to four hours for a grocery store or hotel banquet kitchen. Inspections occur during business hours and without warning. If an inspection uncovers a risk factor that can make people sick, it will be recorded as a critical violation that needs to be corrected.

Photo by David Croxford.

ROUTINE INSPECTIONS

The most common violations, Oshiro says, are poor personal hygiene, improper controls for refrigeration and improper temperatures for holding hot foods.

There’s no set procedure, but sanitarians typically start an inspection with the food preparation area. The reason, according to sanitarian Michael Okamura, is that employees will sometimes change their behavior after learning an inspector is present.

Supervisors who tell their employees that an inspection is occurring do not break any rules, Okamura says, but “it shows that the person in charge does not have confidence in his employees. It shows they want to put on a show for us at that particular time, which shouldn’t be the case.” The good news is that supervisors usually don’t tell their employees that an inspection is happening, he says. “I think a lot of people have confidence in what their employees are doing.”

The first check is often to ensure there’s a functioning sink dedicated to handwashing; if equipment blocks access, it means the sink is not being used. Another early check is that employees’ hands are properly scrubbed and washed at appropriate times, and that none of them are sick, Oshiro says.

A sanitarian will observe the kitchen’s operations, making sure food is properly stored and labeled, and that equipment is working. Rules regulate what temperature and how much time for items to be cooked, stored and held before being eaten. Sanitarians use an electric thermometer, stuck in a food’s geometric center, to check its temperature – and sanitarians ideally check most or all potentially hazardous foods. Poultry has to reach a temperature of 165 F on the inside, and other meat has to reach 145. “That’s really, really key to kill any bacterial growth,” Oshiro says.

Sanitarians also look at how kitchen staff move, cut and prepare food, mainly looking for cross contamination. “It’s really, really critical that their raw meat, chicken, poultry products are separate, physically separate, and not using the same cutting boards, same utensils, if they’re going back to ready-to-eat things,” Oshiro says. Inspectors also check that employees wash their hands between touching raw and touching ready-to-eat food, and also after they remove gloves and after they take out trash.

Sanitarians also monitor how kitchenware and food contact surfaces are sanitized. That means testing to see if the water temperature and concentration of the sanitizing solution are up to par. To check the water temperature, thermal sensitive tape is placed on a dish, and the tape’s color changes if the correct temperature is met. Strips also test the concentration of a sanitizing solution.

The final step involves the establishment’s physical environment, though Oshiro says there’s a low emphasis on the appearance of walls, floors and ceilings because they don’t make people sick. But signs of an infestation of rodents or other pests is a deal breaker.

Okamura recalls inspecting an establishment at least 20 years ago that was infested with German cockroaches. “They were all over the place. It was unbelievable. They were crawling on the walls and stuff like that. I didn’t know how they were not able to control it. But, they were everyplace and, in addition, there was evidence of rodents present, like rats. You could see the droppings, they were on the counters and floors and behind the equipment. … We had to issue a notice of violation so they would immediately correct the inefficiencies.

“And I remember actually leaving, the operator offered me a cup of soda and I was scared to even drink the soda. I was so afraid.”

FOOD SAFETY CHALLENGES

After the inspection, the sanitarian will type a report and discuss findings with a supervisor, explaining what critical violations need to be fixed and when. Typically, establishments are given two days to make corrections, though a longer time can be arranged.

After the inspection, the sanitarian will type a report and discuss findings with a supervisor, explaining what critical violations need to be fixed and when. Typically, establishments are given two days to make corrections, though a longer time can be arranged.

A green placard means the establishment passed and is given when none or only one critical violation is found; correction of the violation would be verified either during the original inspection or during a follow up. A yellow card is a “conditional pass” and is given when two or more critical violations are observed. Some violations result in fines, Okamura says, such as when an establishment continually does not fix a violation, operates without a permit or has an infestation. A red placard means “closed” and is given if there’s an imminent health hazard or if the establishment’s permit is suspended.

“If there’s what we call an imminent health hazard where we get a call from our disease investigation (team), a good example might be Genki Sushi, when we finally knew exactly where this thing was coming from, we will order closures,” Oshiro says, referring to the 2016 Hepatitis A outbreak.

Imminent health hazards include overflowing sewage, lack of water or power, a lot of sick employees working, or an infestation of roaches or rodents. When a facility is closed with a red card, Oshiro says, it’s up to the establishment to call the department so it can reopen.

“We want to work with these individuals and a lot of times they can, with our assistance, or them doing it by themselves, correct critical violations on the spot. That’s what we want to do – is have critical violations corrected immediately,” Okamura says.

One challenge, he says, is high turnover in the food industry, so operators, especially of small establishments, may not have enough time to train new employees. Another issue is the language barrier involving some immigrant workers, typically seen in Downtown Honolulu, he says. A related issue: Some practices used in other countries are done here, even though they violate state rules. “It not only involves educating those individuals but it involves altering their behavior and that’s very difficult, altering behaviors,” Okamura says.

Designed to help remedy food-safety problems is an upcoming update of the state’s Food Safety Code, which was last updated in 2014. One major change is the requirement for the person in charge of each establishment to complete a food-safety certification class at the food-handler level. Food employees can choose to get this certification through the state Department of Health – which already offers free two-hour workshops at the food-handler level and two-day workshops at the manager level – or another approved program.

Gregg Fraser, executive director of the Hawaii Restaurant Association, an organization that supports the state’s food service industry, says the food-handler certification mandate is a good start but thinks it should be required for all kitchen employees, and supervisors should get the manager certification. “Training helps inspections. You’re going to get a better grade and a better chance of getting a green placard if you properly train your staff,” he says.

The proposed rules also incorporate efforts to protect against emerging pathogens, like listeria monocytogenes, which Oshiro says has shown up in prepared cold cuts, and norovirus, which can be transferred through bare-hand contact. The new rules would lower the required refrigeration temperature from 45 F to 41 F, and require food handlers to use gloves or utensils instead of their bare hands when touching ready-to-eat food. At press time, the updated code was awaiting the governor’s approval.

PLACARDS WORK WELL

Most of the 20,337 routine inspections conducted across the state from July 2014 to December 2016 resulted in passing grades, and the number of yellow placards being given out has decreased over that period. Fraser credits the very-public placard grading system. Food operators worry about receiving a yellow placard, because, “if it happens, it’s really going to impact your business,” he says.

That wasn’t the case with To Thai For on Waialae Avenue, says Natalie Tew, who runs the restaurant with her mother and sister. Her restaurant received yellow placards for things like improper sanitizer concentration in the dishwasher, improper refrigerator temperature and lack of paper towels at the handwashing sink. Being inspected can be stressful, she says, but the yellow placards haven’t hurt her business, and the inspections help her family and 10 employees know what they need to improve. “It’s good so we know what’s wrong. It’s like helping us keeping up with our work. Otherwise, we wouldn’t know that the dishwashing has a problem,” she says.

Mark Oyama, owner of Mark’s Place and president of Contemporary Flavors Catering on Kauai, agrees. He says the hardest part of owning a food establishment is the heavy reliance on employees. Inspections are helpful, he says, “because, God forbid, if they find something that we need to fix. But most of the time, for us, we monitor all our refrigerators, freezers, we take temperatures daily, you know, multiple times in a day to make sure everything is in working order, to make sure that our food is safe.” He also sends his employees for food-safety training at Kauai Community College, with a private company or the state health department, or does the training himself.

One person who owns multiple food establishments says the state’s food safety rules are too stringent and dislikes the unannounced inspections. This person, with about two decades of experience in the food industry, requested anonymity for fear of retaliation from the state.

The source says some rules don’t make sense, like the rule that employees have to wash their hands after using the restroom and again before touching food, even if an employee doesn’t touch anything with his or her bare hands in between. “Do you do that at home? I don’t think so. It’s ridiculous,” the source says, adding that employees are on pins and needles anytime an inspector shows up, “because going to the bathroom, they watch you to make sure you’re washing your hands, they watch you to make sure you use a thermometer for everything.”

The source also cites cooking temperatures as an issue. If a chicken thigh is cooked to the required temperature of 165 F, the taste can be affected, resulting in dry chicken: “They just don’t care about the end results that we have to do.”

The source also says being required to get equipment repaired or replaced within a day or two is not always possible for small establishments.

Oshiro says the great majority of restaurants have improved their food safety practices – and he credits that to the placards and the online Inspection Health Portal that was launched in early 2016. The online portal allows the public to read Oahu inspection reports; the goal is to have Neighbor Island reports up by September.

“I think there’s a lot of job satisfaction with the inspectors, because, for them, you go into a place, it might be really bad, you issue a yellow card, you work with the establishment. The whole philosophy for us is to enforce through education,” Oshiro says.

“You have to educate the operator to let them know why we’re asking what we need them to do. And that has worked very well, that philosophy. … Nobody intentionally wants to make anybody sick. So a lot of it is either ignorance of the law or not having control over your employees.”