Need a Prototype? 3D Printing May Be the Answer

Collin Kobayashi plans to make a paddleboard with his 3D printer. Some people, including his wife, may chuckle at the idea, but the president and chief 3D officer of 3D Innovations LLC has the expertise and technology to do it. He’s already “printed” many different things, from surfboard fins to the strobe light casing for a record turntable, so he understands the possibilities of this emerging technology.

He says it’s a great way for small businesses to create prototypes for products or parts. “3D printing is a bridge between prototyping and full production,” says Kobayashi, whose company is located at the Manoa Innovation Center.

3D printers manufacture a part or product using data from a model created by a computer-aided design program, or CAD. The machine puts down one layer at a time until, layer by layer, the entire product is built. 3D printing is used for both prototyping and manufacturing in many industries from engineering to fashion. For example, clothes can be made directly from nylon using a 3D printer, Kobayashi says.

Kobayashi’s printer, a production- grade machine made by Fortus, stands as tall as a refrigerator. It adds layers of plastic on a black foundation accessible through a tinted door that is similar to the door of a microwave oven.

Fortus 3D printers cost $70,000 to $250,000, and even the cheapest desktop model of any brand starts at about $1,200, so it probably doesn’t make sense for most companies to buy their own, Kobayashi says. Instead, they can consider outsourc- ing their 3D printing to companies like Kobayashi’s.

Audio Innovation

That’s what Jim Hagerman of Hager- man Technology LLC did. He invented a self-contained turntable strobe light that he calls the Uniform Frequency Orbiter. The UFO’s light pattern indi- cates when the turntable is spinning at the correct speed, whether 33.3 or 45 RPM. The device is also handy for DJs wanting to put on a cool light show.

Kobayashi helped Hagerman make sure the three parts fit together perfectly around the circuit board that controls the lights.

“It’s much better to spend money on 3D prints rather than $12,000 for molds,” Hagerman says. Even if he had ordered the molds – three pieces at $4,000 each – there would have been

no guarantee they would have worked, he adds.

Kobayashi says 3D printing technology helps an inventor “validate the design” before pro- ceeding, thus minimizing losses that would result from a defective design.

Hagerman and Kobayashi are fine-tuning the UFO – perhaps using wood rather than plastic – to spark wider consumer interest. Stay tuned.

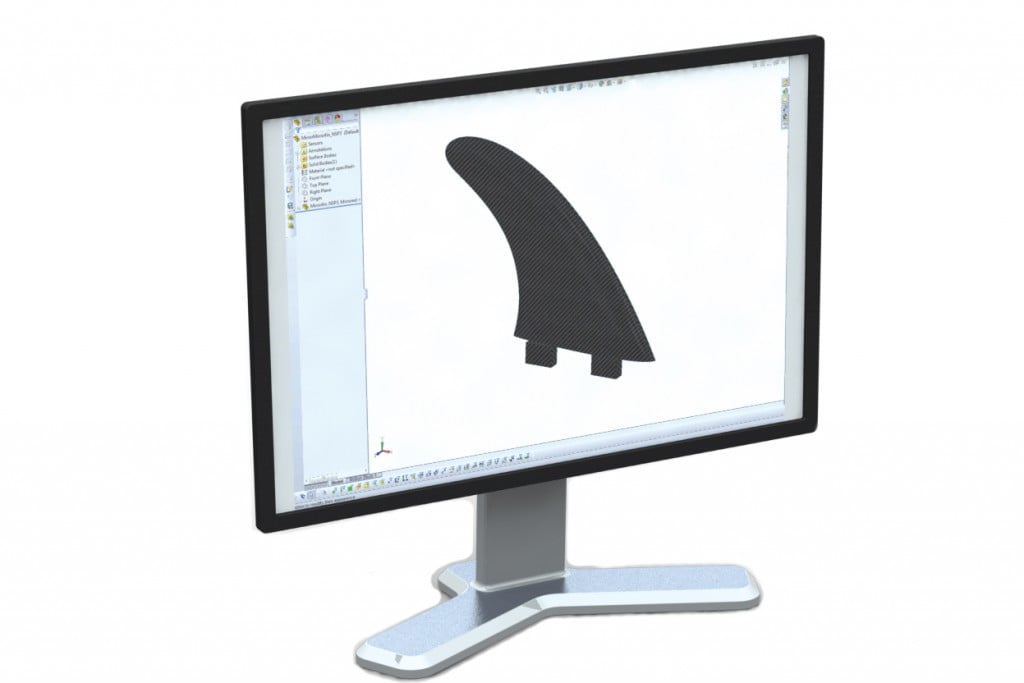

Sculpting for Surf

Kobayashi also did work this year for Jimmy Freese’s business, Aku Shaper. He printed test fins for the Kailua company, which specializes in proprietary soft- ware to design surfboards and the machines to make them.

After examining the curved pieces, Freese said the results were much better than he had imagined and that he’s looking forward to installing them.

Before sanding the fins, the successive layers of plastic were visible, like layers of a topographi- cal map.

“The edges, that’s what I was worried about,” Freese says, “but they look good.”

Kobayashi says Freese can now test the fins in the water before going into production.