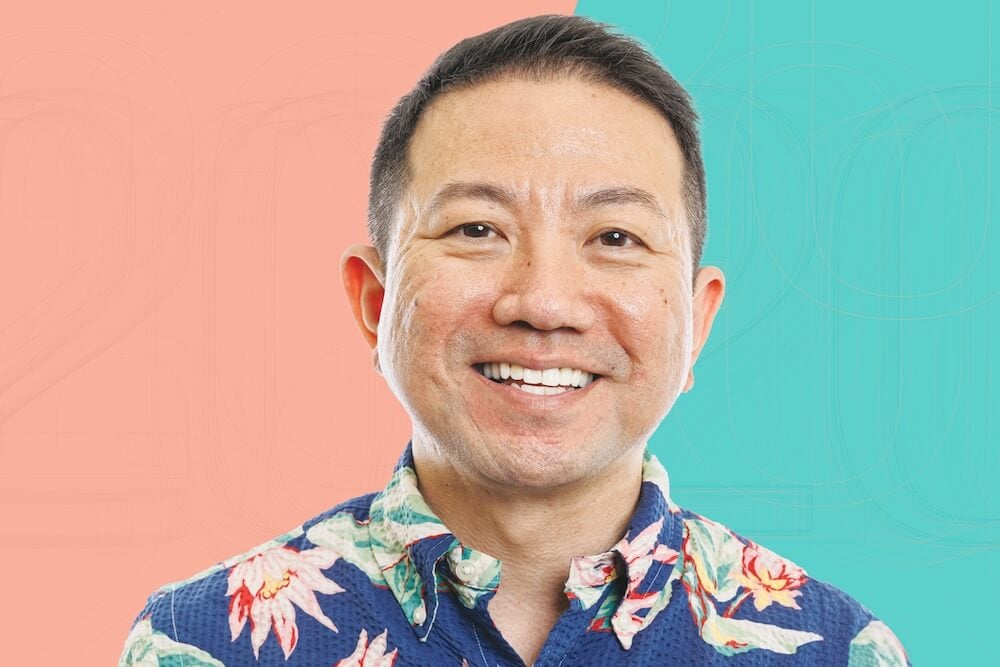

Talk Story with Joseph Boivin, President of Young Brothers

Though Young Brothers doesn’t have direct rivals in interisland shipping, Boivin insists on sharpening its competitive edge by enhancing operational efficiencies, reducing costs and shrinking its carbon footprint.

Q: The Port of Honolulu is undergoing extensive improvements. How will operations change?

Boivin: Research indicated that if the state didn’t immediately expand daily container capacity, our local economy would suffer to the tune of billions of dollars.

When this project is complete, Pasha will operate at the Kapalama Military Reserve terminal and Matson will have all of Sand Island, allowing enough cargo to meet demand for the next few decades. Right now Matson brings 65-70% of imports to Hawai‘i and Pasha about 30-35%, but they are both constrained.

This project, however, will have minimal impact on our terminal.

Q: Regulators have called for improvements in your performance and customer services. What are you doing to achieve that?

Boivin: We’re about a 70% paper-based business. One initiative is to digitize portions of our business. Last year we started using iPads and cargo-tracking software, that assists us in loading and unloading barges – we can have a picture of a barge and drag and drop a container or an automobile. And we will know what is on the barge and where it is and when it arrives. And we can send a customer notification when cargo is ready to be picked up.

In the spring, we hope to turn on a new reservation feature for customers dropping off automobiles and roll-on and roll-off equipment. Instead of taking 20 minutes on paperwork, a customer can do it digitally.

We are also extending our gate hours. And we’re trying to improve the way we operate so folks don’t have to wait long in lines when they’re dropping off or picking up containers.

Q: What about prices?

Boivin: Everybody wants lower prices. Effective March 1, we had a 4.3% rate increase, our first in five years. So our prices have been flat while operating costs have increased – labor, equipment, inflation, etc.

We counteract that hike by making our operations more efficient, like digitizing the business, which will hopefully lower costs. By the end of June we’re going to have four new tugboats, which are more powerful and efficient than our old tugboats, which were on average 44 years old.

We’re seeing fuel consumption numbers down 30% to 50%. Fuel cost savings go directly to the customer.

Q: Your industry has high barriers to entry – Young Brothers spent about $180 million on its new vessels – so you have little competition.

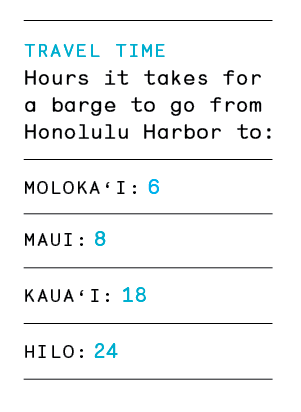

Boivin: There’s a good reason we are a regulated monopoly, as this is a capital-intensive business. We have nine tugboats and eight barges. We make close to 1,500 sailings a year between the Islands. We’ve got over 300 pieces of lifting equipment and over 1,000 containers. Each big lift is about $600,000.

If you have two companies you duplicate a lot of assets, which is less efficient and could increase prices.

We do face competition. People can fly things to the Neighbor Islands. People can vote with their pocketbooks. Amazon is already talking about delivering, so FedEx and UPS are concerned. Amazon’s got planes and warehouses now. Why couldn’t it offer a really cost-effective interisland cargo delivery service?

Q: What happens if there’s a powerful hurricane? In Puerto Rico after Hurricane Maria, a Category 4 storm, there was aid on nearby boats, but it couldn’t be sent inland because the ports were blocked.

Boivin: We plan every year with FEMA. There are drills throughout the year. The No. 1 response for airports and harbors is debris management. Last year we had Lane and Olivia, but we got lucky.

During Lane our vessels, per the Coast Guard’s direction, had to leave the harbor. So we were 200 nautical miles north of the Big Island waiting for the storm to pass. Before leaving, we worked with FEMA prepositioning generators, water, etc. on our Neighbor Islands. We also stocked shelves. Then when the storm passed we restocked the shelves which were empty. It is disruptive to our operations- we had four days of revenue loss. That happened twice last year.

Q: What are your environmental challenges?

Boivin: The new tugboats reduce emissions. Over the coming years we will be looking at transitioning our lifting equipment to run on electricity, which will make the harbors cleaner.

Los Angeles and other harbors have clean air rules. We don’t have those in Hawai‘i, but I wouldn’t be surprised to see that in coming years.

In 2020, global rules under the International Maritime Organization require all vessels to reduce their sulfur and other emissions. That doesn’t impact us because we already use a very clean fuel and now we have even cleaner tugboats.

But other shipping companies have three options to meet the new emissions rules. One is you build a ship that runs on liquified natural gas. Trouble is there’s currently no LNG in Hawai‘i or on the West Coast for bunkering big ships.

The second thing shippers can do is install better exhaust systems to capture emissions so they can continue using current fuels.

The third way is to switch to a much cleaner fuel – but it’s much more expensive.

Q: What would you want your legacy to be?

Boivin: Helping to build Hawai‘i’s interisland commerce. Our outgoing containers tend to be full, but incoming containers are mostly empty. We’re working with innovative companies in agriculture, produce, energy, etc. Our goal is to help them expand from our Neighbor Islands. For Hawai‘i to increase food production it needs to happen in the Neighbor Islands, but it needs to get to O‘ahu where the big demand is.

Our job is to figure out how we do this cost effectively.

This interview was edited for clarity and conciseness.